1. Fampidirana

The Elcometer 415 Industrial Paint & Powder Thickness Gauge is designed to provide simple, fast, and accurate coating thickness measurements on smooth and thin industrial paint and powder coatings. This manual provides essential information for the safe and effective operation, maintenance, and troubleshooting of your device.

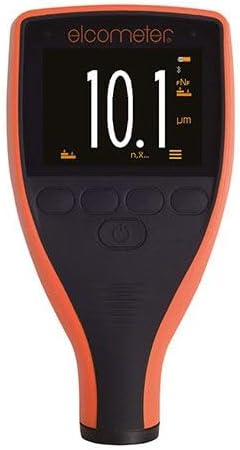

Figure 1: The Elcometer 415 Paint & Powder Coating Thickness Gauge, showing its display and control buttons.

2. Information momba ny fiarovana

Please read and understand all safety instructions before operating the gauge. Failure to do so may result in injury or damage to the instrument.

- Do not expose the gauge to extreme temperatures, direct sunlight, or high humidity.

- Avoid dropping the instrument or subjecting it to severe impacts.

- Keep the gauge away from strong magnetic fields.

- Do not attempt to disassemble or repair the gauge yourself. Refer all servicing to qualified personnel.

- Ensure the measurement surface is clean and free from debris to prevent damage to the probe and ensure accurate readings.

- The gauge has an IP64 rating, indicating protection against dust ingress and splashing water from any direction. However, it is not waterproof and should not be submerged.

3. Inona no ao anaty boaty

Rehefa avy manokatra ny boaty ianao dia jereo tsara fa eo daholo ny singa rehetra:

- Elcometer 415 Gauge

- Check Piece

- Foil Set

Raha misy zavatra tsy hita na simba dia mifandraisa avy hatrany amin'ny mpamatsy anao.

4. Fametrahana

4.1. Herin'ny voalohany

The Elcometer 415 Gauge is typically supplied with batteries pre-installed. To power on the device, press and hold the power button located on the front panel until the display illuminates.

4.2. calibration

For accurate measurements, the gauge requires calibration. The Elcometer 415 supports both 1-point and 2-point calibration methods to ensure precision on smooth and thin coated substrates.

- 1-Point Calibration: This method is suitable for most applications. Place the gauge on a known uncoated substrate (e.g., the supplied check piece) and follow the on-screen prompts to set the zero point.

- 2-Point Calibration: For enhanced accuracy, especially on specific materials or thickness ranges, use the supplied foil set. First, perform a 1-point calibration. Then, place a foil of known thickness on the uncoated substrate and calibrate the second point according to the gauge's instructions.

Refer to the on-screen menu for detailed calibration procedures.

5. Operating the Gauge

5.1. Maka refy

Once calibrated, place the probe of the gauge firmly and perpendicularly onto the coated surface. The measurement will be displayed instantly on the screen. The gauge is capable of taking over 60 readings per minute, significantly reducing inspection times.

Figure 2: The Elcometer 415 Gauge being used to measure the thickness of a coating on a flat surface.

5.2. Display Interpretation

The large, clear display shows the measurement in micrometers (µm) or mils (mils). Additional icons indicate battery status, measurement mode, and connectivity status (e.g., Bluetooth if applicable).

5.3. Data Logging and Transfer

The Elcometer 415 features data logging capabilities. Measurements can be stored internally and transferred to a computer via USB. Use the ElcoMaster software for instant report generation and further analysis of your data.

Figure 3: The Elcometer 415 Gauge displaying a measurement, with a smartphone showing detailed data analysis via the ElcoMaster app.

6. Fikojakojana

6.1. Fanadiovana

To clean the gauge, wipe the exterior with a soft, damp cloth. Do not use abrasive cleaners or solvents, as these can damage the scratch, solvent, and powder resistant display. Ensure the probe tip is kept clean and free of debris for accurate readings.

6.2. fitahirizana

When not in use, store the Elcometer 415 in its protective case in a dry, cool environment, away from direct sunlight and extreme temperatures. Remove batteries if the gauge will not be used for an extended period to prevent leakage.

7. Famahana olana

This section addresses common issues you might encounter with your Elcometer 415 Gauge.

| OLANA | Antony mety hitranga | vahaolana |

|---|---|---|

| Tsy mandeha ny fitaovana fandrefesana. | Bateria kely na maty. | Soloy vaovao ny bateria. Hamarino tsara ny polarity. |

| Vakiteny tsy marina. | Improper calibration; dirty probe tip; unstable surface. | Recalibrate the gauge; clean the probe tip; ensure the surface is stable and flat. |

| Manjavozavo na miredareda ny efijery. | Herin'ny bateria ambany. | Soloy bateria. |

| Cannot transfer data via USB. | Incorrect cable; driver issue; ElcoMaster software not running. | Ensure correct USB cable is used; install necessary drivers; open ElcoMaster software. |

If the problem persists after attempting these solutions, please contact Elcometer customer support.

8. Famaritana

| endri-javatra | antsipirihany |

|---|---|

| MODELY | Elcometer 415 (Model B Ferrous) |

| Laharan'ny ampahany | A415CFBI |

| Fandrefesana Range | Up to 1000µm (40mils) for cured paint & powder coatings |

| Hafainganam-pandrefesana | 60+ readings per minute |

| Fiarovana ny tontolo iainana | IP64 (Scratch, solvent, and powder resistant display) |

| Famindrana angona | USB to ElcoMaster software |

| calibration | 1-point and 2-point calibration |

9. Garantie

The Elcometer 415 Gauge is manufactured to high quality standards. For specific warranty terms and conditions, please refer to the documentation provided with your purchase or visit the official Elcometer webtoerana. Mety ho azo vidiana misaraka ihany koa ny drafitra fiarovana mivelatra.

10. Fanohanana

For technical assistance, product inquiries, or service requests, please contact Elcometer customer support. You can find contact information and additional resources on the official Elcometer webtranokala:

Please have your model number (A415CFBI) and serial number ready when contacting support.